Technological advancements have seeped into virtually every aspect of our everyday lives, making pretty much everything we touch more efficient, more powerful, more durable, more convenient, safer and basically better overall. When it comes to the aviation industry and all of the advances in aircraft cylinders over the years that have made it what it is today, it’s no different. That said…

The advancement of aircraft cylinder technology over the course of history has been vast and largely based on the improvement of materials used for components and processes, as well as mechanical innovations…with the architects of those innovations always remaining mindful that optimal heat dissipation and the limit of mechanical stress are very important contributing factors for extending cylinder life and that of the actual aircraft.

And So It Begins…

Back in very early aircraft development days, exhaust valves, which could be problematic with respect to reliability and durability, were used in Wright engines and faced major adjustments for several decades. This began in the early 1900s, when experiments with internally cooled valves began. Water and mercury were initially utilized for cooling from the head of the valve, to the stem, through the valve guide and into the fins on the cylinder head. Needless to say, water and mercury were less than ideal for this heat transfer process.

Later, sodium compounds, that are solid at room temperature and liquid during engine operation, were introduced for the purpose of heat transfer. This endeavor to transfer heat, as well as to contribute to the extended lifespan of the engine was both successful and has stood the test of time.

Additionally, aircraft cylinder barrels were crafted from cast iron at first. Then, in the 1920s, there was a shift toward the more ideal use of steel alloys, the most widely used of which was a chromium-molybdenum alloy – that we also continue to use to this day.

Extensive studies of the shape of and material used to build piston rings were conducted during WWII. The result was greater efficiency gained by using oil controlled rings. Chrome plating for the purpose of reconditioning cylinders during WWII was also initiated and worked well for air cooled engines of all sizes.

As steel alloys became available in the 1920s, valves and seats also became more resistant to heat and corrosion. However, highly leaded fuels, which were introduced to increase power, caused more erosion. That is when material created from a combination of cobalt, chromium and tungsten came on the scene and was used as overlay material for the valve seating area and valve seat inserts – proving reliable in large engines.

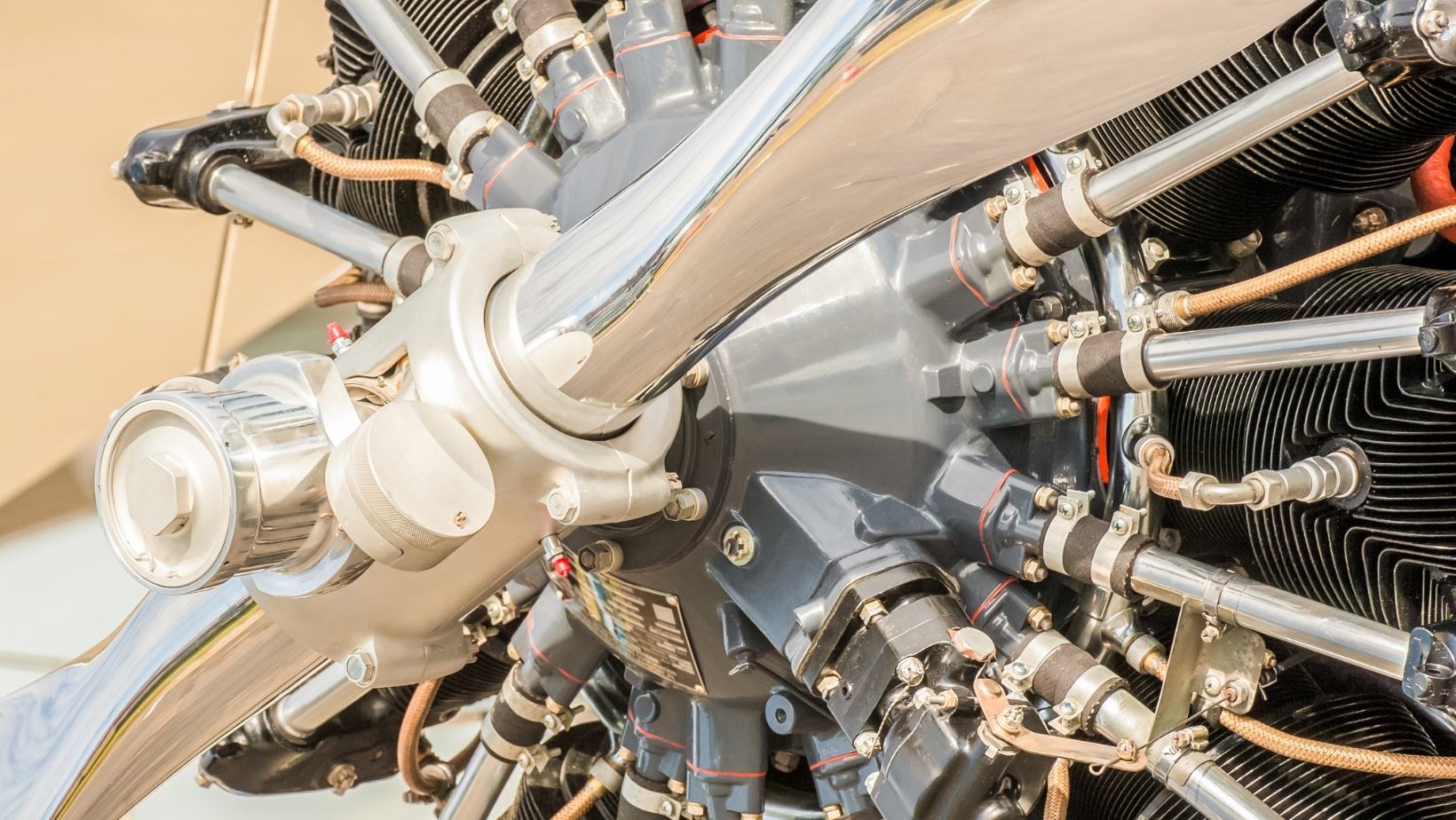

One can essentially track the course of aviation through the advancements that have occurred in aircraft cylinders throughout history. In fact, aircraft cylinder advancements are directly related to the entire evolution of aviation technology. Take, for instance, the Wright brothers’ inline engines evolving into the more compact and powerful engines with pairs of cylinders in a V-shape; or the reliable and powerful radial engines with cylinders arranged in a circular fashion around the crankcase, to rotary engines; and, of course, efficient air cooled cylinders which led to gas turbine engines and piston engines with advanced aircraft cylinder, designs and cooling methods.

Today, the knowledgeable, experienced aircraft cylinder overhaul experts at Moore Performance Products are dedicated to their craft and the clients they serve, further facilitating the innovations of aircraft cylinder technology through the highest quality products, most advanced processes and unsurpassed mechanical services.

Unsurpassed Level of Commitment

Given the critical nature of aircraft cylinder service and maintenance, finding the right service provider is paramount. Moore Performance Products is a trusted aircraft service provider with an excellent reputation.

Moore Performance Products has been family owned and operated since 1995. What that means to its customers is exceptional service and attention to detail, an unsurpassed commitment to high quality products and the ultimate customer satisfaction – with a finished product that is ALWAYS 100% satisfaction guaranteed.

Specializing in Aircraft Cylinder Maintenance and Overhaul

A very specific skill set is required for proper aircraft cylinder maintenance and overhaul and the Moore Performance Products aircraft service professionals, having served the aviation industry with exceptional aircraft preventive maintenance and repair service for over 30 years, specialize in aircraft cylinder overhauls and repairs.

Moore Performance Products has provided a variety of overhaul services nationwide and overseas for the aircraft and aerospace industries…and is wholly committed to each and every one of its clients – from large industrial corporations and government entities to private aircraft owners.

Moore Performance Products is also an FAA-certified repair station and FAA-certified in welding.

Local Convenience

Moore Performance Products is conveniently located at 132 W. Park Avenue, Building 1 in Edgewater Florida and can be reached by phone by calling 386-409-7501 or 888-409-7555 anytime between 9 a.m. and 5 p.m., Monday through Friday.