Although a variety of conditions can make piloting our aircraft challenging, navigating Federal Aviation Administration (FAA) regulations can be somewhat tricky as well. In addition to national directions, policy procedures, advisory material, the FAA develops and standardizes regulations, inspections and surveillance for all aspects of aviation as it relates to preventive maintenance and maintenance. As an aircraft owner, you need to be aware of, understand and adhere to FAA regulations as it relates to your cylinder maintenance and here is what you need to know…

The FAA Limits Pilot Performed Maintenance

First off, a pilot can perform maintenance on 31 items specified by the FAA, but this extends only to aircraft that pilot owns or operates. However, there are limitations, as this does not apply to aircraft used under 14 CFR Part 121, 127, 129 or 135.

It is also important to note that while the FAA allows preventive maintenance to be conducted by pilots, that is also limited, as it cannot involve complex assembly operations. Some of the most common preventive maintenance items which a pilot can address include simpler tasks such as greasing wheel bearings, adding oil to landing gear shock struts and lubricating other items not requiring disassembly including cover plates and fairings. According to FAA regulations, pilots may also complete preventive aircraft maintenance tasks such as refilling hydraulic fluid, replacing safety belts, bulbs, spark plugs, batteries and hose connections except for hydraulic connections. Simple fabric patches only may also be made by a pilot.

If you do decide to perform your aircraft maintenance work yourself, FAA regulations also require you to keep a detailed description of your work within a log book. Each entry must also include the completion date, your certification information and signature. To ensure that preventive maintenance is adeptly performed, it should be properly scheduled, based on usage – inspections which occur at regular, frequent intervals, such as every 100 hours of flight time. These steps allow for FAA safety approval and compliance, as well as the assurance that your aircraft preventive maintenance is occurring in a continual, fluid manner, helping to ensure your safety and the safety of all those onboard your aircraft.

While FAA regulations allow you to perform this maintenance, it is crucial to critically assess your own ability and whether or not you possess enough mechanical knowledge to perform these tasks with not only safe, but favorable results. That said, often it is a better practice to entrust a reliable, well-schooled mechanic than to attempt preventive maintenance on your own.

FAA Regulations and Aircraft Cylinder Overhauls

A properly maintained aircraft is a safer one. FAA regulations are put into place to ensure optimal operation and airworthiness of aircraft components, including aircraft cylinders. According to FAA regulations, only an FAA-certified mechanic may overhaul aircraft cylinders and return an aircraft to service once FAA aircraft airworthiness standards are met. FAA regulation becomes more complicated for a complicated process such as aircraft cylinder maintenance, but for good reason.

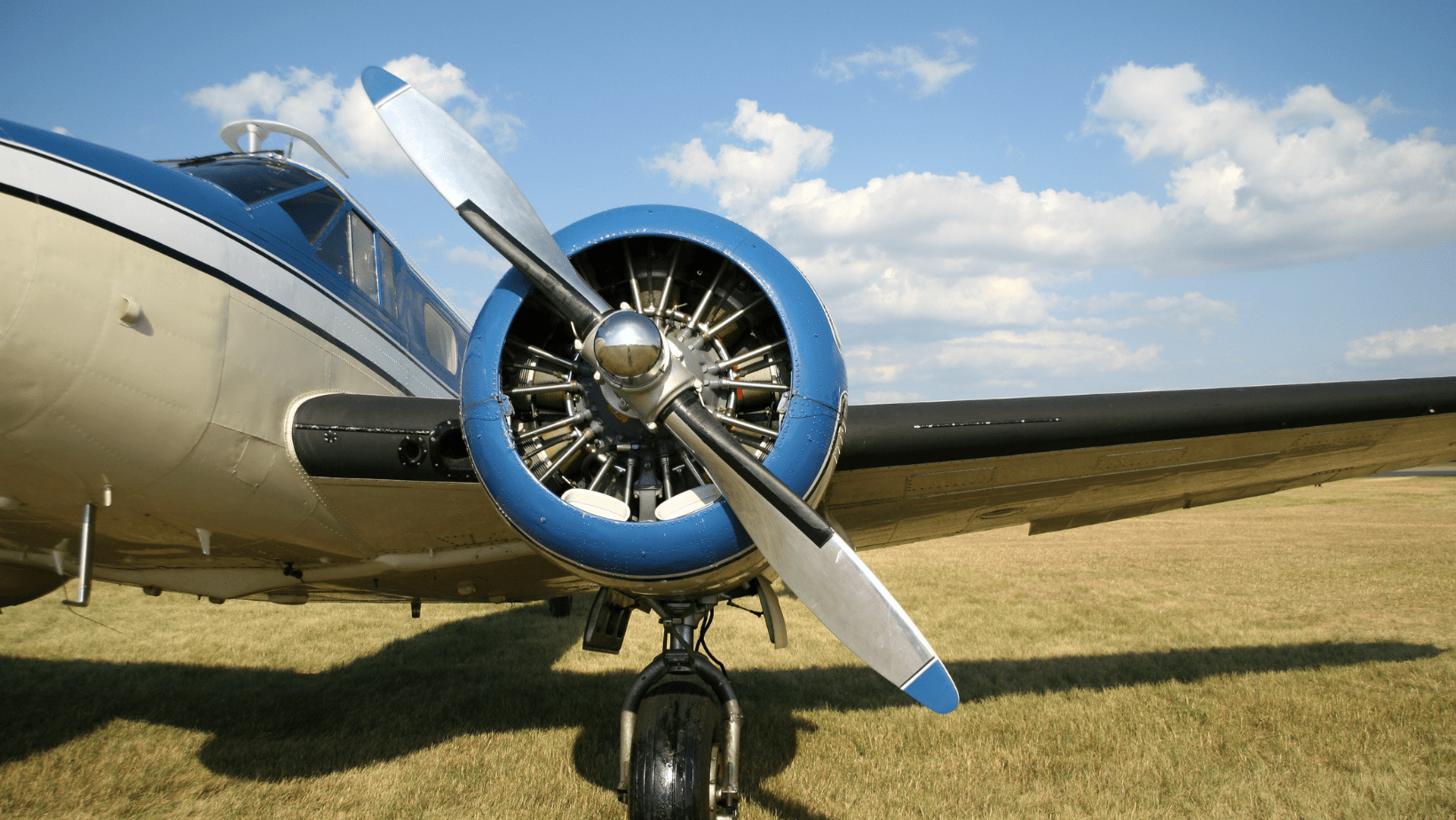

One of the most important places we should focus when it comes to regular maintenance and aircraft safety is aircraft cylinders – the hottest part of the engine. An aircraft cylinder operating at higher than normal temperatures or with leaky exhaust ports can greatly increase the probability of cracks and other damage, very likely leading to some serious engine issues.

In the interest of the longevity of our aircraft engines and safety, we need to keep our cylinders cool, our oil clean and regularly conduct aircraft cylinder inspections and cylinder overhauls as necessary. In fact, the Federal Aviation Administration (FAA) airworthiness directives have actually called for increased inspection frequency of aircraft cylinders.

Specifically, aircraft cylinders need to be inspected for cracks. Aircraft cylinder cracks can result in low compression and could even result in catastrophic engine failure. No matter the extent, an aircraft cylinder crack is serious enough to warrant grounding until that aircraft cylinder can be repaired.

Additionally, cylinder valves operate in extreme conditions which can result in the wear of the actual valve, valve seat, spring or lifters. Faulty cylinder valves can reduce compression and, ultimately, aircraft power. Plus, when a valve actually breaks apart, the broken pieces of metal can bang around your cylinder and into the piston, causing serious damage.

Head and barrel separation is another potential aircraft cylinder issue. When an aluminum head screws onto a steel barrel, you have very different metals operating at very different heat tolerances, which can obviously create some sobering possibilities, such as the increased potential of a forced landing.

The Importance of Utilizing the Services of an Experienced FAA-Certified Repair Station

Cannot Be Overstated

The importance of utilizing a highly ranked and properly qualified repair station with an innate knowledge of everything from the most general, to the most minor details of FAA regulation compliance is critical; but here is the good news…Moore Performance Products is local and available to expertly assist you with all it all.

Moore Performance Products is FAA-certified repair station and FAA-certified in welding. Proud to have served the aviation industry for over 30 years, the consummate professionals at Moore Performance Products specialize in aircraft cylinder overhauls and repairs and provide a variety of overhaul services nationwide and overseas for the aircraft and aerospace industries. Moore Performance Products is also family owned and operated and what that means to its customers is an unsurpassed commitment to high quality products, service and customer satisfaction.

When it comes to adhering to FAA regulations, your safety and keeping your aircraft operating at peak performance, you need an aircraft maintenance team on your side that you can trust to get the job done right and finding the right professional aircraft cylinder overhaul technician is key. Moore Performance Products is conveniently located at 123 W. Park Avenue, Building 1 in Edgewater Florida and can be reached by phone by calling 386-409-7501 or 888-409-7555 anytime between 9 a.m. and 5 p.m., Monday through Friday.