Why Aircraft Cylinder Overhauls Are So Important

Optimally operating aircraft cylinders are vital, to the extent that they may help prevent aircraft engine failure. In fact, the Federal Aviation Administration (FAA) has instituted several directives associated with increased inspection frequency aircraft cylinders, as well as set longevity limits. Regardless, all aircraft cylinders have specific recommendations for when they should be overhauled. So, manufacturer specifications should also be adhered to for the sake of safety as well as optimal engine performance.

Finding a Qualified Professional to Complete Your Aircraft Cylinder Overhaul

That said, if you don’t employ a qualified professional with aircraft cylinder repair knowledge and experience who will take the proper steps for effective aircraft cylinder repair, you could also be placing yourself in quite a pickle. Moore Performance Products, which specializes in aircraft cylinder overhauls and repairs and provides a variety of overhaul services nationwide and overseas for the aircraft and aerospace industries, has been serving the aviation industry for more than 30 years. A Federal Aviation Administration (FAA)-certified repair station and FAA-certified in welding, Moore Performance Products has also been family-owned and operated since 1995, which translates into excellent service and attention to detail, unsurpassed dedication to quality and exceptional customer satisfaction.

The Proper Steps in a Standard Cylinder Overhaul

In general, an aircraft cylinder overhaul is the process of meticulously inspecting, disassembling, cleaning and repairing or replacing cylinder parts as necessary and then reassembling the aircraft cylinder.

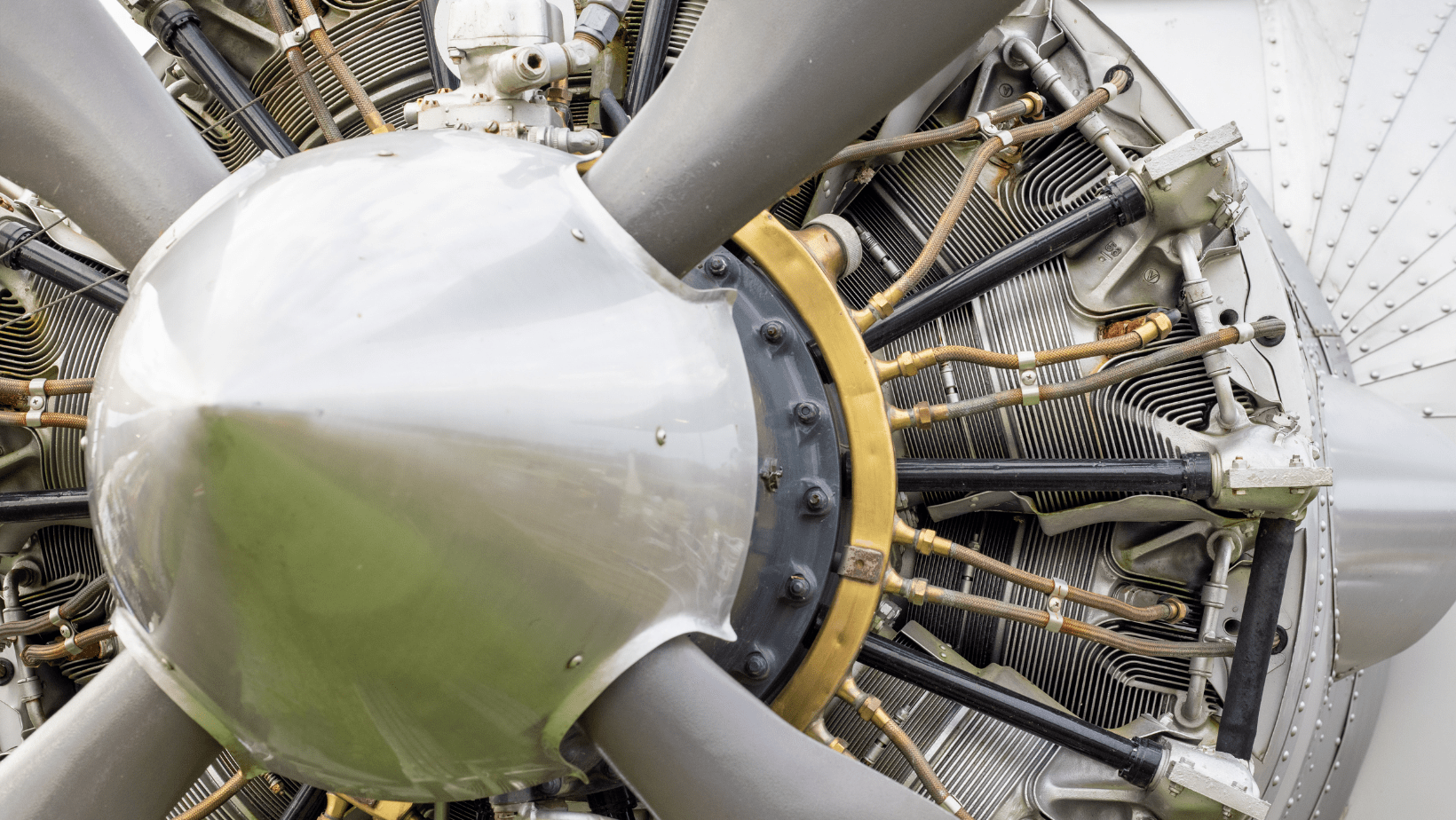

Specifically, a typical standard aircraft cylinder overhaul will start with the inspection and disassembling of the cylinder or cylinders and its/their related parts, which may include valves, springs, rocker arms and shafts, piston and piston pins.

The cylinder head will be removed and inspected for cracks and other signs of wear or distress. The piston is also removed and examined for damage. The connecting rod is checked to be sure it has remained straight and exhibits no signs of wear. The crankshaft is also studied for signs of damage and wear. During an overhaul, cylinder walls receive a great deal of scrutiny as well. If corrosion is discovered, it is removed and any wear on aircraft cylinder walls is repaired.

Then, the next step of an aircraft cylinder overhaul is reassembling the aircraft cylinder. The installation of replacement parts will take place at this point and worn or damaged parts, such as valves guides, seals, bushings, studs, fittings and piston rings, will be replaced.

The final step in any properly executed aircraft cylinder overhaul is rigorous testing of the upgraded aircraft cylinder by a qualified professional to ensure optimal performance.

Signs It Is Time for an Aircraft Cylinder Overhaul

Aside from specific manufacturer specifications, there are obvious signs which indicate it is time to overhaul an aircraft cylinder. These may include excessive oil consumption or a crack in the actual cylinder, both of which demand immediate attention.

There are also more subtle signs which indicate the need for an aircraft cylinder overhaul. These may require certain tests run by a knowledgeable repair professional, including oil analysis. A professional oil analysis will provide a breakdown of the materials in an oil sample, helping to highlight any abnormalities and even pinpointing exactly in what manner and where your aircraft cylinder may be worn or damaged.

Oil can be an exceptional indicator of distress, even to us lay people. For example, if your oil turns black soon after an oil change, it could mean that you have a worn or broken piston ring and subsequent blow through. This could lead to fouled plugs or excessive pressure on your crankcase.

It is also vital to keep tabs on your compression. Traditional compression checks can help determine if air is escaping and you may be able to determine where it is escaping by simply feeling or hearing it.

Proper Aircraft Cylinder Maintenance

From passenger safety, to engine performance and cost-effective maintenance and repair; proper aircraft cylinder maintenance is essential…and it can be a concerning matter. One particular area of concern is the fact that an aircraft cylinder is constructed from different metals, each often wearing at different rates.

Typically, what you are dealing with is an aluminum head screwed to a steel barrel, where a good deal of the action within the aircraft engine takes place. When the aluminum head changes temperature, it contracts more quickly than the steel barrel, creating the potential for uneven wear patterns and, possibly, eventual mechanical failure in the form of a crack or some other damage. In summary, aircraft cylinders simply need to be overhauled from time to time.

The lifespan of an aircraft cylinder will depend on the type of cylinder and its use. An aircraft cylinder overhaul can extend the service life of your aircraft cylinders. Specifically, with proper inspection, maintenance, machining and replacing parts when necessary; the longevity of your aircraft cylinders may, in fact, be greatly extended.

Contact Moore Performance Products to Learn “Moore”!

Moore Performance Products, located at 123 W. Park Avenue, Building 1 in Edgewater Florida, can be reached by calling 386-409-7501 or 888-409-7555 between 9am and 5pm, Monday through Friday.